有不通顺的,含糊的地方,或者术语上有误的还要请各位长辈直接指出啊!不然我的文译水平也得不到长进,更会误导大家! Bramah Locks Bramah locks are an important, and relatively little known, part of t ...

|

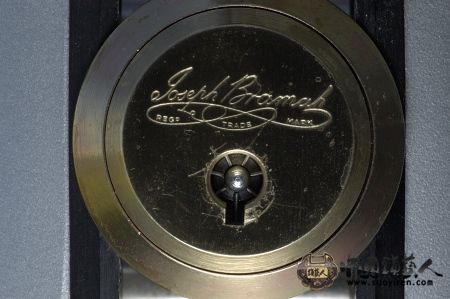

有不通顺的,含糊的地方,或者术语上有误的还要请各位长辈直接指出啊! 不然我的文译水平也得不到长进,更会误导大家! Bramah Locks Bramah locks are an important, and relatively little known, part of the history of physical security technology. First manufactured by Joseph Bramah in 1784, these locks were probably the first commercially produced cylinders to offer good security against manipulation, perhaps even measured against today's standards. Joseph Bramah's interests, by the way, went well beyond locks; among his other inventions are the first beer pump, a flush toilet, a hydraulic pump, and a number of industrial machine tools. Perhaps the most remarkable thing about the Bramah lock, however, is that it has been manufactured, with very few design changes, almost continually for over two centuries. The current version of the company is Bramah Security Equipment, London (owned by Jeremy Bramah, one of Joseph's descendents). The locks are not inexpensive (a rim cylinder retails for about US $100) and thus seem to be aimed primarily at the higher ends of the British residential and commercial markets. 布拉默锁具 在实体安防技术发展史上,鲜为人知的布拉默锁具占有不可或缺的地位。布拉默锁具第一次由约瑟夫 布拉默在1784年生产,这大概是第一种安全性能高,操作性能好的商业化生产的锁具,即使以当今的标准来衡量也不落后。约瑟夫 布拉默的兴趣远远不止锁具方面,它的其它发明还包括世界第一款啤酒泵,抽水马桶,液压泵还有不计其数的机械工具。或许布拉默锁具最显著的特征就是在极少修改原设计的基础上连续生产了两个世纪。现在的公司是“伦敦布拉默安防设备”(由约瑟夫的子孙,杰里米 布拉默掌管)。其锁具并不便宜(一个外装门锁就要100美金),以此看来是主要为英国高端住宅和商业市场所服务的! In addition to being an interesting design in their own right, Bramahs also played a central role in the evolution of the modern evaluation of lock security and resistance to lock picking. For 50 years the company had a "challenge lock" in their shop window, offering 200 Guineas to the first person to defeat it. A.C. Hobbs made a name for himself when he claimed the prize at the Great Exhibition in 1851, a feat said to have taken him over 50 hours. 除了该锁具本身就是个有趣的设计,布拉默在现代锁具的防技术开等措施的技术升级方面也扮演着重要的角色!在以前长达50年的时间里,公司的展柜里摆放着一把“擂台锁”,并为第一个开启这把锁的人,提供200几尼((英国的旧金币,价值一镑一先令))的奖金。A.C.霍布斯因为在1851年的伦敦世博会上获得了这份奖金而闻名,据称花了50多个小时来开启! I stopped by Bramah's London shop a few weeks ago and picked up a couple of their cylinders. Some photos and comments follow. 几周前我在布拉默伦敦专卖店买了一些锁芯,下面是是一些图片和介绍!  The basic design could be described as something like a tubular cylinder (the type commonly found on vending machines and U-shaped bicycle locks) whose tumblers (called "sliders") are more like wafers than pins. The current design uses seven sliders. Versions have been produced with as many as 18. 他的基本设计和普通梅花锁类似(通常在自动贩卖机和自行车U型锁上会发现)那些珠子(称为“滑块”)和叶片锁上的相似。现今的设计使用7片滑块。这种型号已经生产了18年了。  Note in Figure 2 the seven sliders radiating out from the center of the keyway hole. 注意插图2中呈放射状的7个滑块。  A Bramah key (at bottom of Figure 3) is basically a hollow rod with seven notches cut in the end that mate with corresponding sliders in the lock. The index flange lines up the notches with the correct sliders, ensures that the key is fully inserted before it is turned, and prevents removal of the key when it is only partially turned. The depths of the notches are the bitting of the key; six possible depths appear to be used. 布拉默的钥匙(插图3下方)总体来说是一根末端开有和锁芯滑块相对应的7个缺口的空心管子。钥匙上的带动块和缺口成一线,以保证钥匙在完全插入后才能转动,而且避免了钥匙没有旋转足够的角度就被拔出。缺口的深度就是钥匙的牙花。该锁使用6级不同的齿高!  Seven notches are evenly spaced (every 51.4 degrees) around the key. Note that there is a notch under the index flange, which can't be as deep as the others. 7个缺口均匀分布在圆周上(每个间隔51.4度)。请留意那个在带动块下面的缺口,它不能造的和其它一样深!  Bramah keys are equipped with a protective cap to keep, e.g., pocket lint from collecting in the notches. (Apparently, this practice dates back quite a while; Dickens mentions "a Bramah key with a small plug... to keep the dust out" in the Pickwick Papers.) 布拉默钥匙配备一个保护盖,来防止例如口袋里的线头被卷在牙花处。(显然,这样的设计已有好一段时间;狄更斯在《匹克威克外传》中提到“布拉默钥匙加上一个塞子…来防止灰尘进入”)  Bramah cylinders can be disassembled easily; a hex screw on the back (see Figure 6) holds the core in the lock. 布拉默锁具的分解非常简单,一个内六角螺丝将芯部固定在锁的内部!  The core (center of Figure 7) contains the sliders and spring and rotates when the correct key is inserted. The silver- colored ring around the center of the core is at the shear line. 锁芯(插图7中央)包括滑块和弹簧,可以在正确的钥匙插入后旋转。在锁芯中央的银色金属片就是切线!  The key notches mate with corresponding sliders in the core; when the correct key is pushed into the core, a notch at the side of each slider is lined up at the shear line, which allows the core to rotate with respect to the sliver ring. Interestingly, there is only one spring, which sits around the center pin of the core and is shared by all seven sliders. Only the sliders pushed down the farthest by the key remain under spring pressure when the key is inserted; the others are held in place by friction aginst the walls of the core. 钥匙牙花和锁芯的滑块相对应;当正确的钥匙插入锁芯,滑块上的缺口就会和切线对齐,然后锁芯就可以被转动。有趣的是,锁芯的7个叶片共用一个绕在中心柱上的弹簧。只有最高位的片子会受到弹簧力,而其它则由孔壁摩擦力来保持位置!   The tabs on the outside of the sliver ring on the core hold the core in place in the shell and form the shear line. 分成两半的银色圆环是锁芯的切线,用于保持锁芯在锁套里的位置。 Notches on the inside of the shear line ring (see Figure 10) allow the sliders to freely move up and down when the key is inserted or removed in the neutral position. Notches (at the bitting height) on the outer edge of each slider allow the core to rotate within the ring when correctly keyed. 在切线圆环内部的缺口(插图10),能让叶片在钥匙插拔的时候自由的上下移动。而在内部边缘的齿高可以保证只有正确的钥匙插入才能转动锁芯。   A deep notch at the edge of a slider corresponds to the correct key bitting; a shallow notch is usually also present to frustrate picking (they are not deep enough to fully pass the shear line ring but do allow the core to rotate just slightly). The slider in Figure 11 has a true notch toward the bottom (corresponding to a relatively deeply bitted key) and a false notch toward the top. The slider in Figure 12, on the other hand, has a true notch toward the top (corresponding to a relatively shallowly bitted key) and a false notch toward the bottom. Sliders can also be master keyed, by having multiple true notches. 在叶片边缘较深的缺口(真槽)和钥匙的牙花相对应;而较浅的假槽是用来迷惑开锁者的(假槽的深度不足以让锁芯转动,但可以令锁芯轻微的转动一个角度)。在插图11里,叶片的假槽在上,而真槽则在下面。而插图12的叶片则刚好相反。叶片也通过增加真槽来制成总锁的形式! How secure are these locks? They are certainly well made, and any attempt to manipulate them would have to be correspondingly precise. But they are not magic, and the design would seem to allow for many of the same kinds of attacks that work against other keyed locks. I can imagine several approaches. 这些锁的安防程度如何呢? 它们的确是制造精良的,任何试图开启它们的工具都要具备相应的精度。但这不是魔术,而且它的设计就是在锁上的时候抵御各种的损害。我能想出了几种方法!  Picking of the individual sliders appears to be possible with the same techniques used against tubular pin tumbler locks, using a "variable key" that allows the operator to set each slider to a fixed depth and feel which ones bind. (It does not appear to be feasible to modify a conventional pin tumbler tubular pick for the Bramah, however -- those locks have eight pin positions spaced at 45 degrees, while the Bramah has seven at 51.4 degrees). One complication is that there is only one spring, shared by all seven sliders, and so only the slider being pushed down the most (by the shallowist bitting) remains under spring pressure. That means that testing whether a slider is binding moves it slightly, and the lock would need to be "reset" each time a slider is tested. (A variable key design similar to that of Peterson's tubular pick would remember the current position of each slider and make this less tedious than it sounds). Another possibility is a pick that "grabs" each slider so that it can be pulled back up into the original position after testing. 使用开梅花锁的技术来一个个的来开启叶片看来是可行的,也可以使用专开工具来调整每个叶片的高度进行开启。(但想通过改造传统的梅花专开来开启布拉默是不可能的,因为梅花锁具有8个珠子,每个间隔45度,而布拉默则使用7个间隔51.4度的片子)。最复杂的状况是7个片子共用一根弹簧,而只有最高位的牙花会受弹簧力。这意味着必须分次来鉴别各个牙花的高度。(有一种类似潘特森梅花专开的工具,可以记下每个牙花鉴别后的高度,这就省了不少繁琐的步骤)。另外一种开启的方法是夹住一个片子,使它可以在鉴别后被拉回原来的位置。 Decoding by shimming also appears feasible. I found it is possible to insert a .0015 inch shim alongside each slider, and, with proper control of the angle, feel the depth of the true notch. Measuring the depth at which the shim hits the notch effectively decodes that position. Once decoded, it should be (relatively) simple to produce a corresponding key. 而使用插片对它进行暗配也是可行的。我发现可以在每个叶片的边上插入一片0.0015英寸的薄片,并适当的调整角度,再感觉一下真槽的位置。最后测量插片碰到真槽时的长度。一次暗配,因该是比较简单就可以做出正确的牙花的! |

2016-07-19

2016-05-31

2016-05-27

2016-03-28

回答

回答

回答

回答

回答

回答

42